Flat Pack Furniture and Sustainability

Sustainability is a widely used buzz word nowadays, as we realise the damage we have already done to the planet. Whether it’s banning single-use plastics, like drinking straws or changing to more eco-friendly fuels, we’re constantly looking for ways to extend the life of this planet.

Where we live and what we use to furnish our homes can have a serious effect on the environment. Many would argue that flat pack furniture is less durable and more throwaway, so how can it be sustainable?

Let’s take a look at flat pack furniture and sustainability and the advantages or disadvantages it offers over traditional handmade furniture. As pressure is building on companies to be more eco-friendly, what measures are the largest flat-pack manufacturers—including a certain Swedish company—taking to be more sustainable?

How Sustainable is Flat Pack Furniture?

In general terms, it can be said that flat pack furniture is pretty sustainable and friendly to the environment. There are factors in the manufacturing process and transportation methods we’ll discuss that are extremely environment-friendly.

However, there’s also the ugly side which includes reduced longevity, increased carbon emissions from the automated processes and the use of some unpleasant materials.

Bear in mind though, flat pack furniture manufacturing is constantly evolving and we will look later in this article at recent eco-friendly changes which have been made.

First, let’s take a look at just how long you can expect flat pack furniture to last and how eco-conscious current manufacturing methods are. We also need to consider the transportation and the actual materials that flat pack furniture is made from.

Reference: https://thedesigntabloid.com/2018/06/19/decorating-dictionary-flat-pack-furniture/

Durability

Furniture made from MDF, or more specifically, flat pack furniture, is not built to last. Going back to the Swedish connection, I have got original ABBA records from the 1970s that still work—I doubt I’m going to have a 40-year-old set Kmart of drawers in 2059 that still gets used.

Most flat packs tend to be more expendable and less expensive products that you will replace every few years. It can be hard to prevent the wear and tear flat pack furniture suffers, and almost impossible to restore a piece of MDF furniture. The designs make it hard to replace just one single piece and keep it looking stylish.

Battered and broken flat pack furniture will often end up as more landfill and a waste of resources. From a green point of view however, most flat-pack furniture can be given a second lease of life in your workshop or den. Why not take that badly scratched storage unit or chest of drawers from the bedroom and use it as a tool caddy in your garage?

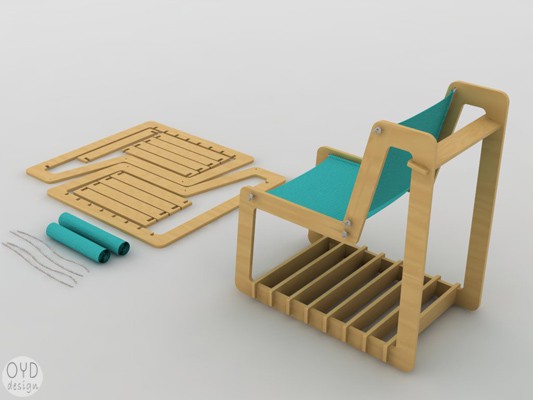

Reference: https://inhabitat.com/oy-designs-flat-pack-fs-chair-can-be-easily-assembled-in-a-snap/

The Materials Used to Manufacture Flat Pack Furniture

Most off the shelf flat packs use medium density fibreboard (MDF) which is made from inferior wood and some offcuts from sawmills. Although you may think this is more eco-friendly, often toxic glues with formaldehyde bases are used to bond the wood particles together.

Over time, the Urea-formaldehyde of these glues can release formaldehyde gas into the air which we can breathe in. Sounds unpleasant, and it is. Formaldehyde has been classified as a Class one carcinogen by the American Cancer Society.

On the plus side, efforts are being made to use sustainable density fiberboard (SDF) by many companies. This uses a less toxic type of glue called MDI.

The source of wood for both SDF and MDF will often come through processing thinning small trees. Removing and using these gives more space and a thriving environment for larger and stronger trees.

The Production Process

Produced on a mass scale in large factories, there’s very little about the flat pack manufacturing process that can be classed as environmentally friendly.

The industrial production process of many goods accounts for large levels of carbon emissions, with flat pack furniture being no exception.

By comparison, a small, one or two man carpentry studio, will use much less energy and have a lower level of carbon emissions. Little independent factories will also use smaller scale machines which will cause less pollution to the outside environment.

On the other hand, modern manufacturing processes will maximise the use of each sheet of wood, with fewer offcuts and less wastage. CNC mills will often reuse MDF and can recycle reclaimed or solid wood so there’s less waste of natural resources.

The Transportation of Flat Packs

Surely the compact nature of flat packs and the fact you can fit more in a truck must be more sustainable than solid furniture? Yes, you will get more flat packs in a truck and reduce the fuel consumption per unit, but how far are these mass-produced items travelling to the end consumer?

You may only get two or three desks in the back of Bob and Ted’s bespoke studio around the corner, but they have much less of a way to travel. Locally produced handmade furniture will always be more sustainable when it comes to transportation issues.

However, it is arguable that the bulk packing of flat packs makes it more sustainable in the long run.

In the UK, they even produce sustainable flat pack houses claiming the cost of transporting traditional building materials causes almost a third of all transportation carbon emissions.

The bonus green points of the transportation of flat pack furniture is a reduced carbon footprint which arises from the larger quantities delivered in one go. Furthermore, companies like Kmart have been rolling out more depots across Australia so there’s less distance for trucks to travel.

Reference: https://www.homedesignkey.com/flat-pack-furniture/

What Are Flat Pack Manufacturer’s Doing to Increase Their Sustainability?

Legislation and public pressure are forcing manufacturers to revise their policies regarding sustainability. A recent Unilever survey reported a third of consumers now consider the social and environmental impact of the companies they buy from.

At home in Australia, companies like Nomi are combining quality flat pack furniture with sustainability. By making their furniture more of investment pieces rather than “stepping stone” throwaway designs they are reducing landfill issues. By keeping these pieces flat packed too, they can keep the transportation carbon footprint low also.

Furthermore, all Nomi furniture is made using materials with a Forest Stewardship Council Chain of Custody Certification. Basically, all raw materials used are responsibly produced with an effective environmental management system in place.

The Take-Home Message

Although flat pack furniture offers its advantages when it comes to cost and accessibility, it can’t really be seen as the most sustainable option. Mass production methods of flat packs have a negative impact on our environment and some of the materials used can be toxic.

However, changes are being made with the use of more eco-friendly materials and commitments to using renewable or recycled sources.

Companies are adapting their sustainability policies of manufacturing. Leading furniture manufacturer’s are launching sustainable retail stores too with solar panels, electric car charging points and water collecting bio-diverse roof gardens.

Reference: https://www.kitchenshack.com.au/about-our-manufacturing/manufacturing20plant3/